- China pet preform mould manufacturers full#

- China pet preform mould manufacturers trial#

- China pet preform mould manufacturers professional#

China pet preform mould manufacturers professional#

The factory has 10 years of mold development, experience in the design, mold design and manufacture of professional manufacturers. SICA Mold is located in "China mold town -, Zhejiang, land, sea and air transportation is convenient. There is no dead angle area in the flow passage, so as to ensure fast color change and prevent material degradation ħ. Thus, the flow casting is reduced and the injection cycle is shortened ĥ. Correct gate structure and size to ensure that the cavity is fully filled and the needle valve gate is closed in time.

China pet preform mould manufacturers full#

The proper size of the hot nozzle ensures the smooth flow of the melt and the full filling of the cavity Ĥ. Balanced flow channel design, part cavity evenly filled ģ. Accurately control the melt plastic temperature to eliminate material degradation Ģ. Key performance elements of hot runner systemġ. Shorten injection cycle, strengthen automation and improve production efficiency. Shorten the mold opening stroke in the injection operation cycle, and eliminate the time of taking out the nozzle material ġ0. Reduce the injection and holding time required ĩ. Strengthen the function of injection and improve the injection process ħ. Increase the injection volume of the parts and improve the compressibility of the plastic melt Ħ. Ensure the consistency of injection parts and improve the accuracy of plastic parts ĥ. Avoid the impact of using recycled materials on reducing the quality of parts Ĥ. Reducing the recovery, classification, crushing, drying and storage of waste materials can reduce the number of crushers, save labor, reduce energy consumption and save production space ģ. Reduce the loss and cost of raw materials Ģ. Spare Parts: According to Specific Requirementįree Sample: According to Specific Requirementġ.

China pet preform mould manufacturers trial#

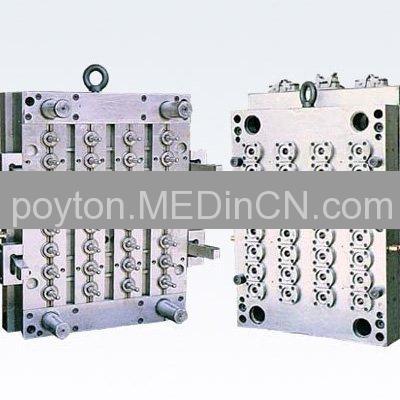

Sample Delivery: Send Trial Samples and Try-out Report to Customer Mould Design: According to Customer′s Requirments Pet Preform Mould/Mold features: Good quality Pet Preform Mould/Mold Runner system: Hot runner Pet Preform Mould/Mold life: 8million shots Pet Preform Mould/Mold material: P20, S136. Pet Preform Mould/Mold size: Depends on your design. Pet Preform Mould/Mold cavity: As per customer requirement

Vapor-compre.Product Name: Pet Preform Mould for water bottle These liquids can flow through heat exchangers to cool the air or equipment. What is the cooling technology of the blow mold factoryīlow moulding machine is a machine that achieves cooling effect through steam compression or absorption cycle.The volume of air to be excluded is equal to the volume of. When molding containers with the same volume, the amount of air discharged from the blow mold is much larger than that of the injection mold. Generally, there are three main methods: plunger type, sc. (1) Injection system Effect of injection system: Injection system is one of the most important components of Ningbo injection molding machine. What are the effects of each part of the injection molding machine.The working principle of the injection molding machine in the operation of the injection molding machine, when the screw rotates, the plastic will generate friction and mutual movement between the in. Plastic injection plastic machine work principle.High efficiency and favored by domestic and foreign merchants. Now it has successfully cooperated with dozens of domestic well-known brand enterprises. Products and thorough after-sales service, our custom pet Preform mold were all exported and sold well in Southeast Asia, North and South America, Eastern Europe, Middle East, Europe, Africa and other countries and regions. We have set up many after-sales service agencies at home and abroad to provide new and old customers with high cost performance. In order to create a high-quality Changshengda brand and cast a first-class image of Changshengda, we continue to innovate products and implement the service promise of "turnkey project". As China Preform mold Manufacturers and pet Preform mold suppliers, we are specializes in the development and production of environmentally friendly, high-precision, medical and food injection molding machines, and PET automatic high-speed injection molding machines. was established in 1992, a wholly-owned Australian enterprise with a registered capital of US$5.2 million.The plant covers an area of 72,000 square meters.

Changshengda Machinery (Zhejiang) Co., Ltd.

0 kommentar(er)

0 kommentar(er)